Fascination About 24??media

Fascination About 24??media

Blog Article

An Unbiased View of 24??media

Table of ContentsHow 24??media can Save You Time, Stress, and Money.See This Report on 24??mediaNot known Incorrect Statements About 24??media Some Known Incorrect Statements About 24??media Indicators on 24??media You Should Know

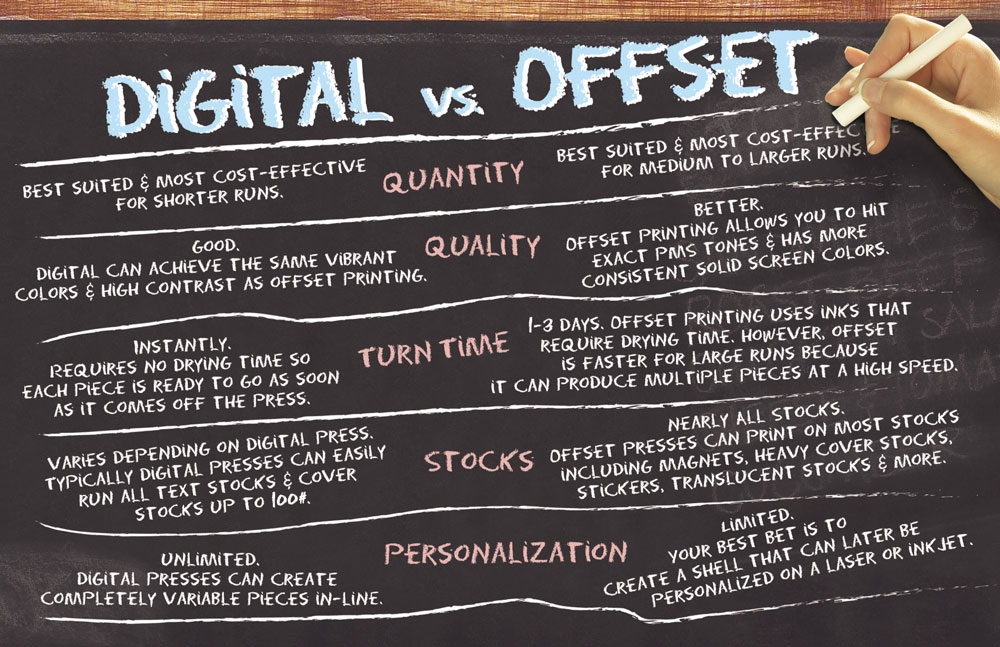

Developments in print innovation are transforming the interactions playing field when it comes to quality, affordability and advanced abilities. Balanced out printing and digital printing are the major processes by which print tasks are carried out both utilizing four-color printing methods. Each choice has its benefits, using different techniques to fulfill the demands of varied manufacturing projects.

Usually, this has been the most constant technique for specifically keeping shade suits, making it perfect for print runs that just require static printing such as pre-printed forms, brochures, flyers, service cards, and mass postcard mailings. Nevertheless, because of the fixed nature of litho printing, it is not perfect for variable print pieces that will certainly be sent by mail to individual receivers such as declarations, letters, and customized postcards.

The Definitive Guide for 24??media

The latest improvements in print innovation are helping to bring numerous of balanced out's advantages into the digital printing world really altering the face of modern printing! There are some essential differences between Offset Printing and Digital Printing (Digital Printing). This guide reveals the benefits and drawbacks of each printing method. There is an undeniable and growing variety of benefits to utilizing the digital print procedure.

Today's digital print equipment is amongst the most cutting-edge on the market. Below are a few of the biggest benefits of using electronic printing: dominate the digital print room, with full-color printing completed in one procedure and flawlessly published directly from a print data. Without a prolonged set-up procedure, the calibration time of a details task is shortened, contributing to quicker print time and overall shipment.

The inkjet printing procedure has aided to transform the sector in addition to the quality and rate of the result. The most up to date inkjet technology can publish on typical offset supplies with dull, silk, and shiny surfaces. Premium digital print paired with software-managed shade monitoring practices includes maximum value to publish items and makes production processes much more reputable than countered.

How 24??media can Save You Time, Stress, and Money.

(https://slides.com/za24media)

Green and biodegradable inks and toners are additionally offered for even more lasting printing. Digital print likewise eliminates the requirement to clean plates or coverings with harmful chemicals at the end of the printing procedure.

Variable data assists businesses reach their exact customers and audience with uniquely-created and individualized content. As innovation boosts, the quality of digital printing has actually ended up being second-to-none, with higher detail, color match capabilities and general precision. Without the requirement to clean plates or utilize excess ink, electronic printing is additionally less inefficient and typically extra eco-friendly.

Conventional printing techniques, such as countered lithography ("balanced out") and flexography ("flexo"), include multiple make-ready steps to move an initial image to a substrate. These approaches require the production of a series of plates placed on a cyndrical tube to move ink that develops the desired image when incorporated on paperboard and various other packaging materials. Window Vinyl.

What Does 24??media Do?

Digital printing, with less moving items, is much more dexterous than balanced out in this respect.

Minimized set-up time saves cash on the front end. And because these are not substantial bulk orders, smaller services can pay for to publish without having to meet the higher and a lot more costly print limits of traditional printing.

Make sure you work together with a printing and product packaging companion that has the right accreditations. While eleventh-hour printing and personalization are a huge advantage, digital might not constantly be the very best approach for you. For example, counter printing has the benefit of cost-effectiveness with huge print runs, specifically those with innovative attractive effects and specialty coatings.

24??media - An Overview

The positive plate, with its smooth surface, attracts oil-based inks and pushes back water. In comparison, the adverse plate, with its harsh appearance, soaks up water and fends off oil. Rubber rollers are then used to transfer the image from the plate to the corrugated surface.

Corrugated paper can in some cases verify to be a challenging surface to publish on, yet Litho prints to a different surface area and is then laminated to it, making it simple to print premium images. It can be incredibly consistent, also for long terms. In truth, the extra you print, the more affordable the prices become for Litho.

What Litho does not give you is specifically what Digital does, personalization. Pricey set up Longer turnaround No Variable Information Printing Smaller color range, colors can be much less bright Digital printing is the procedure of printing digital photos directly onto the corrugated substratum making use of a single-pass, direct-to-corrugate strategy.

Report this page